From September 28 to October 04, 2022, the boiler furnace lining was ignited, dried and heated to operating temperature as part of the project to replace the refractory lining of the flat roof of the boiler. Upon completion of the drying and heating process, the boiler was put into commercial operation.

DRYING AND HEATING OF THE LINING.

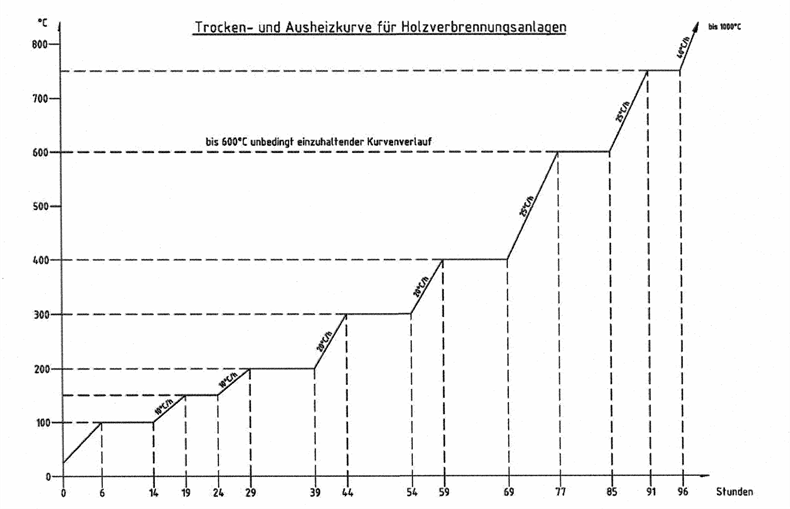

The specialists of Wellons.RU LLC, after completing the installation of a new lining of the flat roof of the boiler, prepared a schedule for firing up and drying the lining. This schedule was transferred to the operators at the boiler control panel and is mandatory for execution. The most accurate adherence to this schedule allows for the process of drying and heating of a new monolithic lining without additional temperature stresses, and also allows for uniform heating of the lining throughout the entire thickness of the working layer. Temperature shelves (100-150°C, 400°C) are calculated based on the thickness of the lining of the working layer and are mandatory. Compliance with these shelves is necessary to ensure the completion of the flow of physical processes characteristic of the specified temperatures throughout the entire section of the lining.

BOILER IGNITION.

The ignition of the boiler was carried out at 14:40 on September 28, 2022. In the initial period of ignition, within an hour, there was a sharp jump in temperature to 127°C at 15:10, and to 141°C at 15:30. The reason for the sharp rise in temperature after ignition was the presence of dry fuel in the boiler bunker, which, as a result of a long shutdown of the boiler, from May 2022 to September 28, dried up. Over the next hour, the temperature returned to normal and was within the agreed schedule. The main deviation from the ignition schedule occurred at the stage of starting to set the temperature in the range of 400-600°C. Due to the parallel operation of two boilers and low steam extraction for the technology, reaching the temperature shelf of 600 ° C occurred with a delay of 20 hours - the automation of the boiler did not allow the temperature to be set under these conditions, and the actions of the operators did not helped keep the temperature within the specified range. With the participation of the engineering staff of the TPP, by changing the outlet pressure on the boilers, it was possible to load boiler No. 1 and reach the shelf of 600 ° C. As a result, there was a shift in the temperature set schedule for the specified time interval. The actual schedule of temperature set in comparison with the planned schedule is shown in Appendix 1.

COMMISSIONING THE BOILER INTO TECHNICAL OPERATION.

At 22:00 on October 03, 2022, when the temperature reached 750°C, the boiler automation reached the temperature shelf provided for by the ignition schedule by the manufacturer. After holding the temperature shelf for 7 hours, namely at 5:00 on October 04, 2022, the boiler left the ignition schedule. From 05:00 on October 04, the boiler is in the industrial technical operation mode and operates according to the needs of the plant's technology (depending on the steam consumption of the main technological equipment, steam turbine, heating load).

THE BOILER SHUT DOWN FOR TECHNICAL INSPECTION.

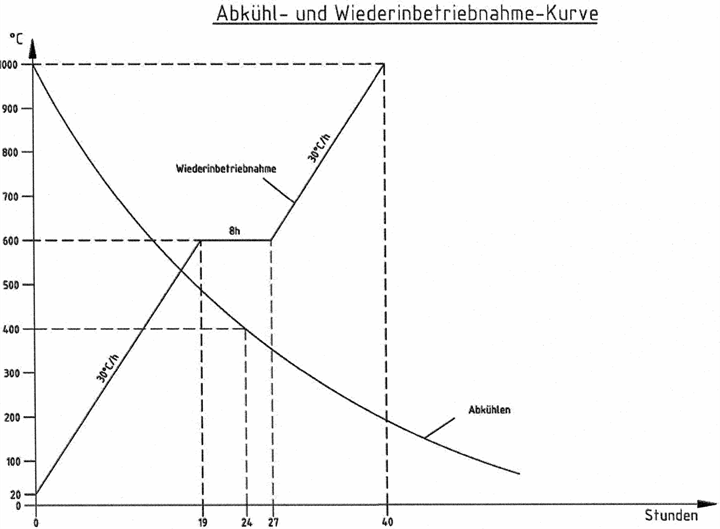

The boiler was stopped, the process of cooling the boiler plant was started, at 5:00 on October 07, 2022. According to the wishes of the specialists of the plant, due to the need to operate the boiler for at least 72 hours of industrial operation, the boiler was stopped after reaching this time. The process of cooling the boiler plant was carried out according to the cooling schedule "wired" into the automatic control system of the boiler. On October 10, 2022 at 8:00 a.m. the boiler is ready for a visual technical inspection. The results of the inspection are presented below. The results of the inspection are shown in comparative photographs:

|

BEFORE DRYING |

AFTER DRYING |

SUMMARY.

The results of the examination of the refractory lining of the flat roof of the boiler showed the absence of defects in the lining after the completion of the drying and heating stage, as well as the industrial operation of the boiler after 72 hours, according to the current mode of operation of the CHP boiler equipment. Based on the results of the inspection, a conclusion was made on the compliance of the newly installed lining with the operating parameters of the boiler equipment of the boiler equipment of the plant

Boiler No. 1 is allowed for further industrial operation, in accordance with the technical regulations of the plant.

The specialists of Wellons.RU LLC have analyzed the algorithm of the boiler automation system at the stage of drying and heating the lining and do not have any additional rules and restrictions on the temperature setting during the boiler kindling and its cooling, which are different from the requirements of the schedules for ignition and heating of the plant lining - of the manufacturer, shown below, namely: the schedule for firing up the boiler from a cold state and the schedule for firing up the boiler from a hot state.