Very often, we are discussing the topic: thermal oil heaters (TOH) or steam boilers – which is better? This question is especially relevant when you have to choose a development concept for your company fuel and energy complex, and accordingly, identify the main process equipment to be used at a new plant which is often the case in the early stages of a new project discussion and estimation of associated construction budget.

We took the construction of a new plywood mill with the production capacity of 120,000 m3/year as an example and prepared an analysis of technical solutions based on the construction of a mini HPP on the basis of steam boilers and turbo-generator as against the use of thermal oil heaters (TOH). As a manufacturer of both steam boilers and thermal oil heaters, we tried to assess these two options and clarify the advantages of the construction of a mini HPP running on steam, even though it requires a slightly greater initial capital investment. Both options are based on the concept of "turnkey" supply of all the necessary basic and auxiliary equipment, including buildings and constructions.

TOH

Analysis of the plywood mill heat balance suggests that to ensure normal technical operation of process equipment, as well as to accommodate the winter-period heating loads, the plant requires 28 MWH of heat during summer, and up to 43 MWH in winter. Thus, to satisfy the plant needs, at least three TOH with a heat capacity of at least 14 MWH each (total 3х14=42 MW) are required. Moreover, the load ratio of one of these TOH will be equal to 0.5, as it will only be used in wintertime. Application of a larger number of TOH with lower capacity leads to a significant increase in the initial investment amount, as these units do not carry the added value (not paid back), and furthermore, to the reduction of the effectiveness of the plywood mill construction project in general. We would like to point out the following flaws inherent in the construction of the TOH, which do not allow us to recommend this solution for implementation:

- TOH bring no added value, and cannot be paid back.

- With an increase in the TOH unit capacity or a quantity of TOHs used, the initial investment cost is nearing that for a steam boiler.

- Complete disposal of waste cannot be achieved. Due to the fact that (at least) one TOH is out of action in the summer time, the maximum waste disposal rate may be no more than 120,000 m³/year (dense). In other words, the issue of waste disposal in the amount of ~ 65,000 m³/year is still relevant.

- Environmental risks associated with waste disposal; the cost of official waste dumping to a landfill reaches 5,500 rubles/t.

- The need to build a heat point (standalone insulated building) with heat exchangers for the distribution of heat among different consumers (technology, heating, hot water, etc.) Additional costs in the amount of up to 5-10% of the total cost of the TOH building.

- It is not recommended to erect the thermal oil heater building further than 50-70 m from the heat consumers. This can bring about serious difficulties at the stage of project implementation. Given feature may necessitate a territorial diversity of the TOHs, which will, in turn, give rise to the logistic problem of managing the waste streams from different points of generation. Additional investments in the waste transportation, arrangement of active storages for each TOH, and construction of additional conveyors may be required. Moreover, such territorial diversity does not allow for interchangeability of equipment, its operation with a single manifold or a single heat distribution point and will not permit, if necessary, the transfer of thermal power from one TOH to another TOH heat consumers.

- The high cost of thermal oil, up to 50,000 rubles/ton.

- High fire risk. The complexity of performing repair work on the oil lines, pumping groups, etc.

- Example: In Finland, at least 90% of the plywood mills have steam boilers. In Japan, there is not a single plywood plant utilizing the thermal oil systems. Both countries solve the issues related to waste disposal by means of steam boilers and power generation.

STEAM

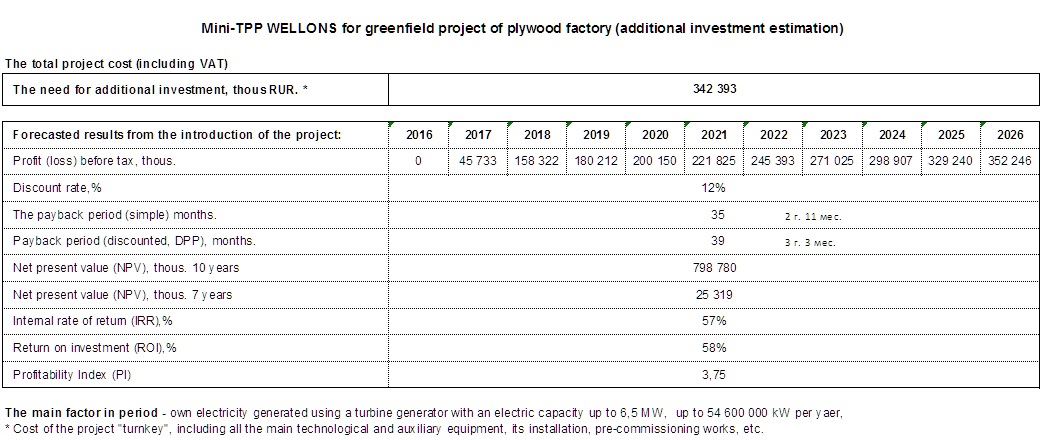

We believe that the construction of a mini HPP on the basis of two WELLONS.RU steam boilers producing 25-30 MTH of steam with the characteristics of 40 bar/440°C, and 7 MWH Siemens turbo-generator is an effective solution. This option carries a greater added value, represents a profitable project itself and improves the financial performance of the plywood mill construction project in general. For example, the implementation of the project under this scheme allows to generate up to ~ 54,600,000 kW/year, or to gain EBITDAextra revenue in the amount up to 260 mln rubles a year on the average. The results of feasibility analysis of additional investments to mini HPP as compared with TOH option are shown in the table below:

We would like to emphasize the advantages of building a mini HPP that allow us to recommend this solution for implementation:

- High profitability, EBITDA of 260 mln rubles a year in average for the project.

- Low payback period of additional investment: DPP (discounted payback period) is 3 years 3 months.

- Independence from the state monopolies, 100% coverage of the plant needs in heat and electricity.

- The possibility of building a unified fuel and energy center to meet all heat consumers' needs.

- Simple scheme of steam distribution, rapid heat redistribution according to demand.

- The possibility of recycling the maximum amount of internally produced waste (90-100%). The absence of environmental risks associated with waste handling.

- Independence from waste sales market.

The best solution, the most rapid return on investment in relation to other possible solutions for waste disposal (chipboard, MDF, pelleting, briquetting, etc.). Smaller investment volume, independence from the market of plate board materials.